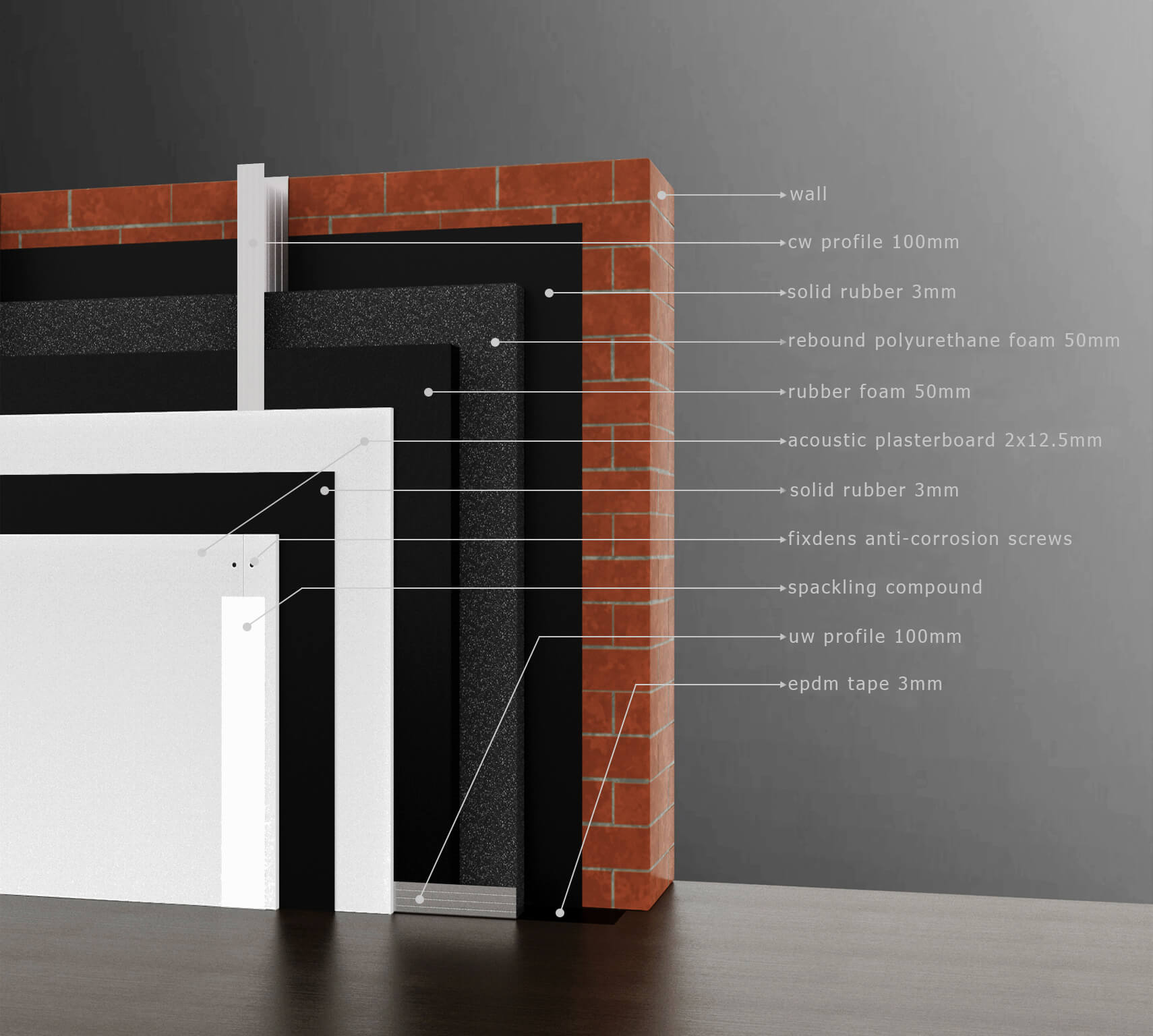

The Superior+ System represents the highest standard in acoustic insulation,offering unmatched effectiveness in noise reduction while maintaining qualityand durability. The additional layer of heavy, solid rubber, along with increasedthickness of other components, works synergistically to transform the wall into aformidable barrier against low, medium, and high-frequency sounds. TheSuperior+ System is an investment that not only provides immediate relief fromnoise issues but also delivers long-term benefits and satisfaction from a high-quality solution that meets the highest standards in wall acoustic insulation.

BASIC SYSTEM DATA

| System thickness: | 131mm |

| Number of layers: | 6 |

| Acoustic insulation: | 56,3dB |

| Weight: | 49kg/m2 |

ACTIVE SYSTEM COMPONENTS

| Component | Thickness | Density |

|---|---|---|

| Closed-cell solid rubber | 3mm | 2000kg/m3 |

| Semi-open cel rebound polyurethane foam | 50mm | 160kg/m3 |

| Closed-cell rubber foam | 50mm | 60kg/m3 |

| Acoustic plasterboard | 12,5mm | 1020kg/m3 |

| Closed-cell solid rubber | 3mm | 2000kg/m3 |

| Acoustic plasterboard | 12,5mm | 1020kg/m3 |

EFFICIENCY: Rw 56dB

DOWNLOAD:

USED MATERIALS

| 1. Solid rubber |

| 2. Rebound polyurethane foam |

| 3. Rubber foam |

| 4. Acoustic plasterboard |

| 5. Contact Adhesive |

| 6. Elastic adhesive |

| 7. EPDM tape |

| 8. Fiberglass tape |

| 9. Steel, galvanized CW profiles |

| 10. Steel, galvanized UW profiles |

| 11. Expansion anchors |

| 12. FixDens anti corrosion screws |

| 13. Spackling compound |

| 14. Finishing paint |

QUALITY OF ASSEMBLY. HOW DO WE DO IT?

1. We adhere solid rubber to the wall using a hybrid elastic adhesive. This allows for maneuvering the pre-attached panel to precisely align the elements with each other, as well as with the ceiling and adjacent walls.

2. We adhere a robound polyurethane foam using contact adhesive, which is sprayed on both surfaces to be bonded. Any gaps between the panels are filled with a technical sealant to eliminate potential acoustic bridges.

3. We apply acoustic plasterboard using contact adhesive, which is sprayed onto both surfaces being joined.

4. We reinforce the joints of plasterboard with glass fiber tape and apply elastic filler such as Siniat Nida Multitask compound.

5. We make the joints between plasterboard panels and adjacent walls or ceilings using the “controlled crack” technique to reduce the risk of cracking. The finish is completed with acrylic.

6. We perform initial and final sanding of the dried compound using dust extraction tools. This reduces dust generation during surface preparation.

PRICE:

System superior+: 1380 zł/m2 gross

Included in the price:

- Materials

- Installation service

- Removal of all debris after work (material remnants, scraps, foils, cardboard)

- Cleaning after completion of work

Not included in the price:

- Travel expenses for the installation team if installation is outside Warsaw

- Cost of accommodation if the project duration exceeds 1 day

- Finishing of additional internal and external corners, doors, windows, electrical sockets

Please contact us: based on photos and dimensions, we will prepare an accurate estimate for the project.